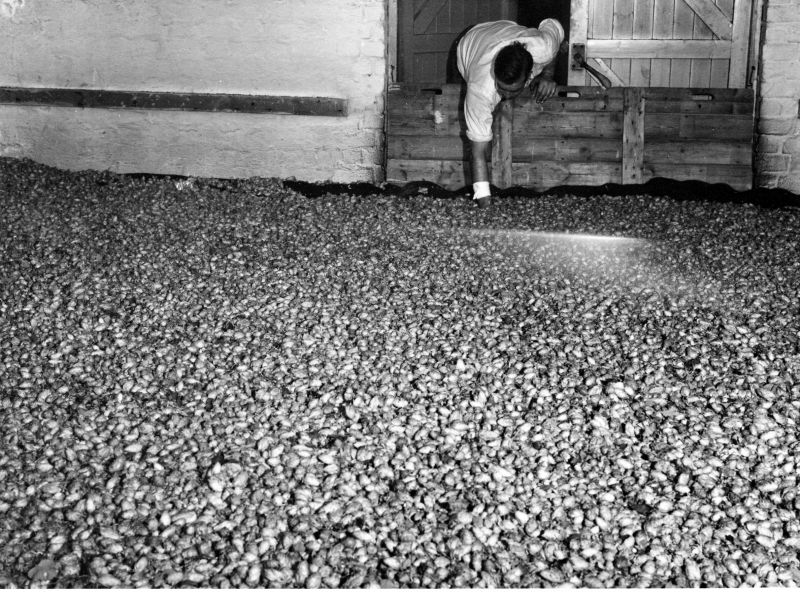

Testing for dryness

The hop drier was a skilled man.

As the thickness of hops in the kiln varied from between a depth of four and six inches skill was need to ensure that the hops at the bottom were not too dry and the ones at the top not too moist. As the hops were fairly warm the continued "cooking" when taken out of the kiln. If they were properly mixed the over dry ones would extract some of the moisture from the under dried ones ensuring a batch of correct dryness. An excess of moisture in the hops would mean them going mouldy.

This photo shows the drier, Percy Webb, testing for dryness by hand.